What technology do I use for dehumidification in critical environments?

Many process environments require low humidity process air. Depending on the desired conditions in the space, you may need to choose between a couple of technologies to dehumidify.

The lowest cost solution tends to be a DX cooling system with modulating hot gas reheat. CFM Company works with a number of manufacturers who offer this technology. The practical limit of using refrigeration to dehumidify is that it works well when the dew point of the space is 45˚F and higher. If we use a DX or chilled fluid coil to condense moisture out of the airstream, then we need to prevent frost from forming on the coil.

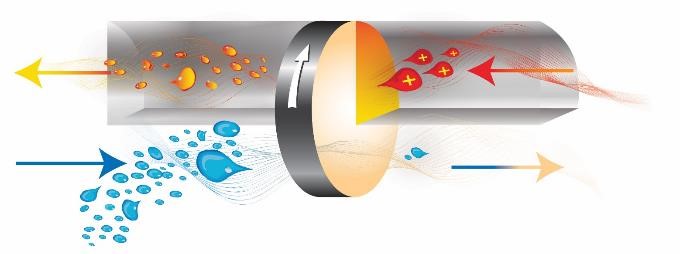

Active desiccant dehumidification is a great choice when supplying dry air to a space with a 45˚F dew point or lower. This process adds reactivation energy to a latent energy wheel in order to remove moisture from the process airstream.

However, the answer to the first question is often “both refrigeration and active desiccant dehumidification.”

Since refrigeration works so well at removing moisture at higher dew points, it can be used as a first stage of dehumidification, upstream of a second-stage desiccant system. This can prevent oversizing of the desiccant wheel and reactivation heater.

Climate by Design International (CDI) is CFM Company’s manufacturing partner for these applications. They work with us frequently in order to assist with product design for either pre-engineered or fully customized desiccant dehumidifiers.