Preventing Predictable Problems with Electric Duct Heaters…

“No Contact Delivery” Newsletter

Editor’s note: Feel free to share this with your junior engineers who may not be reading this post.

Electric duct heaters should be easy, but everything isn’t always as it should be. There are two common spec problems with duct heaters. Let’s look at both:

Spec Problem #1: Outdoor or Unfiltered Air. We will occasionally see an electric heater that is designed to preheat outdoor air. Can you do it? Sure. Should you do it with a standard duct heater? No, you should not.

Most electric duct heaters use an open coil. You might think of this as a toaster for your duct, because it’s using the same technology. It’s inexpensive, has low pressure drop, and it works.

For outdoor (or unfiltered) air, we recommend upgrading to finned tubular construction in order to protect the coils. If open coils get caked with dirt or dust, the elements can short out. Finned tubular elements have insulation on the coils, which prevents the short circuits. Those elements are also resistant to moisture and are easier to change out than open coil elements.

Spec Problem #2: Minimum Velocity / Airflow Turndown

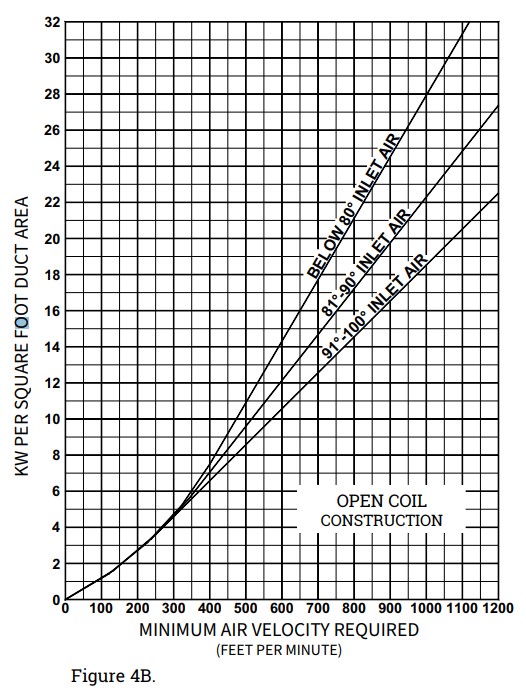

An electric duct heater requires sufficient airflow in order to prevent overheating, and manufacturers publish minimum airflow velocities in order to avoid this.

It’s simple enough to use the graph, but for reference think of a 24” x 12” duct with a 18kW duct heater installed. For a 9 kW/sf duct heater, the minimum velocity is around 450 fpm. You probably didn’t design your system for that low of a velocity, but if your system has variable airflow, it might be worth a safety check!

The minimum airflow is a requirement of UL and NEC and it is critical to heater safety.

There are other possible concerns such as controls, heater placement, and maximum kW per square foot. But we like to keep these posts short!